Machinery Categories

People buying in this category

CNC VARIABLE RAKE HYDRAULIC GUILLOTINE SHEAR

General features

HYDRAULIC C FRAME PRESS

Standard Features

• PLC application and Touch Screen Control Unit

• Top and Bottom Table with T Channel

• Adjustable Stroke

• Double hand control for working safety

• Electrical Counter

• Front safety Light Curtains

• Side Safety Cages

Bending Graph : Comformity to the Europen Directives (CE)

NC HYDRAULIC GUILLOTINE SHEAR

General features

FORCE Series Variable Rake Hydraulic Guillotine Shears that provide the appropriate solutions for your needs proved to be user-friendly with its advanced technological features produced with high efficiency, precision and performance criteria. The FORCE Series Variable Rake Hydraulic

Guillotine Shears has proved to be the best and most durable in the industry with its ease of use.

When you enter the length, thickness and material information of the sheet which will be cut into the easily programmable control unit; gap distance, cutting angle stroke and cutting length are automatically adjusted instantaneously.

While providing flexibility for different production requirements, the time loss eliminated by targeting high productivity.

• The machine frame manufactured with advanced technology with exact tolerances and stress relieved with welded components. All tensile points are designed with large radii and strain accumulation and possible welding cracks are eliminated.

• The lower table and upper table inertia created for optimum value for the minimum deformation affecting the cutting quality.

• The top plate designed to positioned vertically so that the roller bearings, piston bearings, and felts can compensate for vertical loads.

• The hydraulic cylinder is intended to be double-sided and honed to surface quality of 2 microns. Thus, minimum wear resistance is created for the felts. The cylinder bodies manufactured as SAE 1040 material forged.

• The hydraulic cylinders specially designed and the upper table mounted with cylinder springs and doubly secure to cylinders as a spherical connection. At this point, the power generated during cutting distributed to the machine body.

• Piston head features: Omega-type felts fitted with full bronze bearings, semi-angled sleeves.

• The Hilalsan hydraulic system allows precise usage at all pressure values up to the maximum operating pressure. At the same time, with these pressure values, precise cylinder positioning, synchronization, and repeatability are achieved.

• Backgauge system manufactured in accordance with environmental conditions. Backgauge bearings made for heavy conditions with double bearers. Scrapping type bearings used against dust and other particles that will accumulate in the linear guideways against dusty environmental conditions.

• The outer surface of the machine is painted with two layers of paint at least 60 microns in thickness to protect against weather conditions. Paint drying is done gradually in a different time and temperature ranges in state-of-the-art ovens.

GUILLOTINE SHEAR WITH REDUCER PRESTIGE – 3 MM

Standard Features

Optional Features

Airslide Canvas

Available in Polyester and Aramid. Staple or multifilament. SO 1043-1

Material :

Weight : 3500 ± %5 gr/m2 DIN 53584

Air Permeability : 400 ± 50 m ³/m ²hr ΔP:35mbar DIN 53517

Thickness : 4-5 mm ±0,50 DIN 53517( We fabrication according to your request)

Working Temperature : cont 150 °C / pick 170 °C

Breaking strength : Warp 100% / Weeft 55%

Tensile strength : Warp ≥615 daN/ cm / Weeft ≥310 daN/ cm

Dimensional Stability : Warp <-1,0 / Weeft <-0,5 1 h AT 150 C

SINGLE CYLINDER IRON WORKER

General features

• Cut in five different stations to reduce cost, energy, and job loss.

• It is manufactured from welded and welded steel stem with static and dynamic rigidity to ensure long service life and maximum productivity.

• High and precious safety ensured against accidents that may occur during use with safety cage systems in the existing five cutting stations.

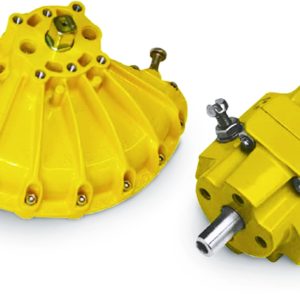

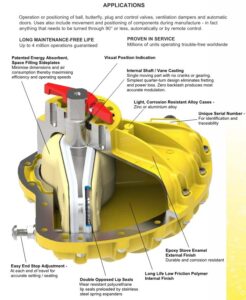

Actuators and valeves

Operation or positioning of ball, butterfly, plug and control valves, ventilation dampers and automatic

doors. Uses also include movement and positioning of components during manufacture – in fact

anything that needs to be turned through 90° or less, automatically or by remote control.

LONG MAINTENANCE-FREE LIFE

PROVEN IN SERVICE

Materials of Construction:

Seal expanders: Stainless spring steel.

Working temperature range:

Maximum recommended working pressure: 100 psi (7 bar)

Maximum overload pressure: 150 psi (10 bar)

Universal punching machine – Double Cylinder

General features

• Cut in five different stations to reduce cost, energy, and job loss.

• It is manufactured from welded and welded steel stem with static and dynamic rigidity to ensure long service life and maximum productivity.

• These models operated by double cylinder and double foot pedal. The punch side and the combined side can operate at the same time or independently of each other.

• High and precious safety ensured against accidents that may occur during use with safety cage systems in the existing five cutting stations.

Standard Features

• Easy Replaceable Punch Holder

• Punch & Tool

• Angle Cutting Blade

• Flat Bar Cutting Blade

• Notching Blade

• Solid Bar Cutting Blade

• 1000mm Electrical Back Gauge

• Foot Pedal with Emergency Stop Button

• Hook Wrenche

Optional Features

• Bending Tool (SET)

• IPN (NPI), UPN (NPU), T Profile Section Blade

• 90O Special V Notching Blade

• Bottom Blade Connection Fixture for

90O Special V Notching Blade Bottom

• T – NPU – NPI Section Punching Die Fixture

• Special Punch & Tool Options

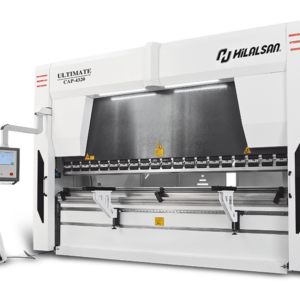

CNC PRESS BRAKES

HYDRAULIC C FRAME PRESS

Standard Features

• Top and Bottom Table with T Channel

• Semi-Automatic two hands control by Lever and Pushbutton , for up/downstroke stop.

• Automatic two hands control by Double Pushbutton , for up/downstroke stop, automatic table return.

• Manual Adjustable Stroke

• Pressure switch

• Side Safety Cages

Optional Features

• Oil Heather

• Oil Coolant with Fan

• Light Curtain for Finger Protection

DEEP DRAWING PRESSES

Standard Features

• Steel Frame Construction Body

• PLC application and Touch Screen Control Unit

• Ram and Bottom Table with T Channel

• Adjustable Stroke

• Central lubrication Motorized

• Double hand control for working safety

• Electrical Counter

• Front safety Light Curtains

• Side Safety Cages

• Ram with sledges from 8 surface.

Optional Features

• Proportional Pressure & Speed Control

• Comformity to the Europen Directives (CE)