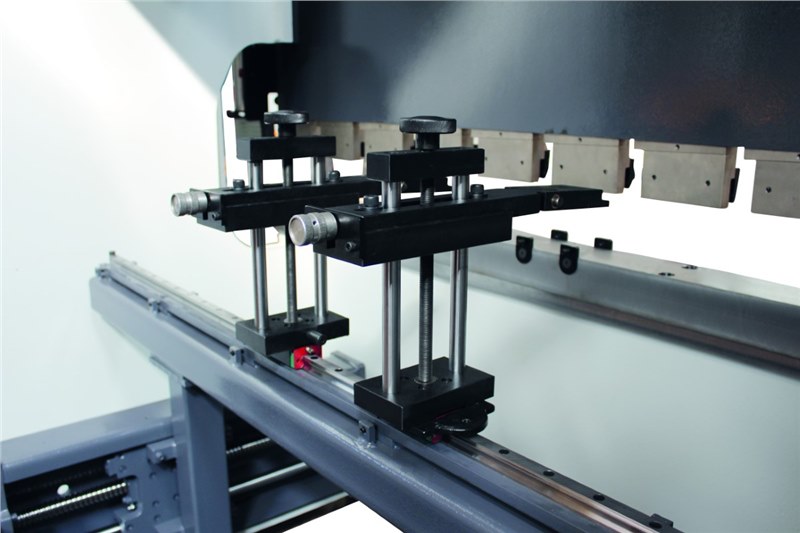

CNC PRESS BRAKES

Shipping Policy

According to your country. Click on "Request for inquiry" and specify your country

We will send you our offer CFR.

Based on 0 reviews

Be the first to review “CNC PRESS BRAKES”

-

Aluminium, Copper and alloy

Zinc ingot

Zinc ash is processed to obtain metallic zinc of 99% minimum purity remelt zinc ingot. It is used in brass and hot dip galvanizing industries.

SPARPART Suppliers produces metallic Zinc Ingots with the highest possible density. Ingots are generally the least costly metallic form and useful in general applications. Our standard Ingot size is nominally 2-3 cm x 3-8 cm x 6-12 cm. Materials are produced using crystallization, solid state and other ultra-high purification processes such as sublimation. SPARPART Suppliers specializes in producing custom compositions for commercial and research applications and for new proprietary technologies. SPARPART Suppliers also casts any of the rare earth metals and most other advanced materials into rod, bar, or plate form, as well as other machined shapes and through other processes such as nanoparticles and in the form of solutions and organometallics. We can also provide pieces and shot in smaller ranges

SKU: n/a -

Hydraulic Press, Machinery

HYDRAULIC C FRAME PRESS

Standard Features

• PLC application and Touch Screen Control Unit

• Top and Bottom Table with T Channel

• Adjustable Stroke

• Double hand control for working safety

• Electrical Counter

• Front safety Light Curtains

• Side Safety Cages

Bending Graph : Comformity to the Europen Directives (CE)SKU: n/a

There are no reviews yet.