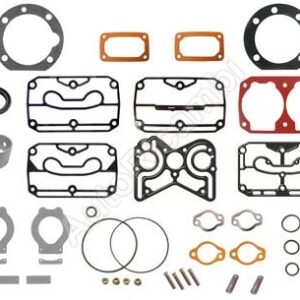

EXPANSION TANK RHD IVECO STRALIS

-

Type : After Market A-RICAMBI

-

Motor/Engine : STRALIS IVECO

-

Original reference : 41215632

-

Equivalent references :

$41 $49

Shipping Policy

According to your country. Click on "Request for inquiry" and specify your country

We will send you our offer CFR.

Based on 0 reviews

Be the first to review “EXPANSION TANK RHD IVECO STRALIS”

-

Guillotine Shears

GUILLOTINE SHEAR WITH REDUCER PRESTIGE – 3 MM

Standard Features

- Hilalsan Manual Back Gauge ( L=560mm )

- Support arm with scale ( L= 750mm )

- Rear Safety Cage

- Support arm (2 pcs)

- Foot Pedal with Emergency Stop Button

- Full Length Fixed Finger Guard Cage

- Top and Bottom Blades

Optional Features

- BRL 401.2 NC & AC Motorized back gauge ( L=700 mm )

- Pneumatic sheet support system

- Spare-Blades: Standard Top and Bottom Blade (1 set )

- 0-180° Front angle gauge

- Electrical Voltage Difference

- L=1500 mm Front Support

- L=2000 mm Front Support

- L=3000 mm Front Support

SKU: n/a -

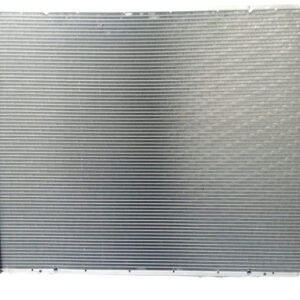

Aluminium, Copper and alloy

Brass Bar

Brass is an alloy of copper and zinc. The proportions of zinc and copper can be varied to create a range of brasses with varying properties. Brass has higher malleability than bronze. The relatively low melting point of brass (900C to 940C, 1652F to 1724F, depending on composition) and its flow characteristics make it a relatively easy material to cast. By varying the proportions of copper and zinc, the properties of the brass can be changed, allowing hard and soft brasses.

Brass bars are the most widely used and least expensive of copper-based alloys. They have relatively good corrosion resistance, moderately high strength, and in some compositions exceptionally good ductility and excellent forming characteristics when shaped by pressing, deep drawing, rolling and machining. Improved tensile properties are the result of cold working. After cold working, they can be softened and recrystallized by appropriate annealing. Adding lead to the brasses results in free cutting of free-machining alloys in which the elemental lead is present as uniformly dispersed particles. The high content of lead results in a relatively low ductility and plasticity.

360 Brass

360 brass is a soft, ductile metal with outstanding corrosion resistance and excellent cold formability. It has a machinability rating of 100%, allowing it to be used at the highest capabilities of any screw machine work. In addition to screw machine parts, it is typically used for plumbing products, connectors, electronic components, circuit board relays, and more.

Alro stocks brass in 360 (C36000) grade in flat, hex, round, rod, and square. 260 brass (C26000) is stocked in sheet and plate form. Tubing and special shapes are available upon request.

SKU: n/a -

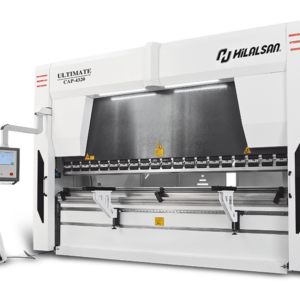

Hydraulic Press Brake

CNC PRESS BRAKES

General features• The machine frame manufactured with the advanced technology with exact tolerances and stress relieved with significant welded components.All tensile points designed with large radii and strain accumulation and possible welding cracks eliminated.• The lower and upper tables’ inertias designed for optimum value for minimum deformation.• The top plate intended to positioned vertically so that the roller bearings, piston bearings, and felts can compensate for vertical loads.• The hydraulic cylinder is designed as double-sided and honed to surface quality of 2 microns. Thus, minimum wear resistance is created for the felts. The cylinder bodies manufactured as SAE 1040 material forged.• The hydraulic cylinders are bolted to the front of the feet with bolts and cams to provide excellent leveling and load balancing.• Piston head features: Omega-type felts fitted with full bronze bearings, semi-angled sleeves.• The pistons are precision ground and hard chrome plated to provide low friction and abrasion resistance when the piston passes through the felts.• The adjustable top tray slides made from materials that are suitable for little friction resistance. These beds arranged for guiding to move the top table from right to left and front to rear.• The Hilalsan hydraulic system allows precise usage at all pressure values up to the maximum operating pressure. At the same time, with these pressure values, precise cylinder positioning, synchronization, and repeatability are achieved.• Backgauge system manufactured following environmental conditions. Backgauge bearings made for heavy conditions with double bearers. Scrapping type bearings used against dust and other particles that will accumulate in the linear guideways against dusty environmental conditions.• The outer surface of the machine is painted with two layers of paint at least 60 microns in thickness to protect against weather conditions. Paint drying is done gradually in a different time and temperature ranges in state-of-the-art ovens.• Standard Y1, Y2, X-axis.SKU: n/a

There are no reviews yet.