Zinc ingot

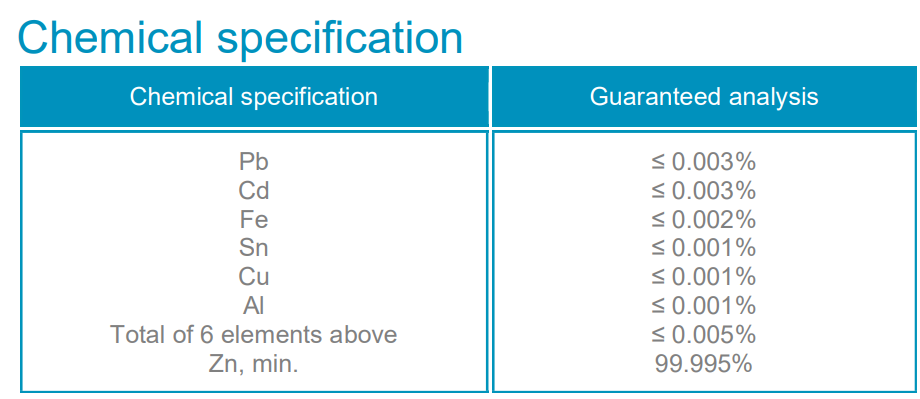

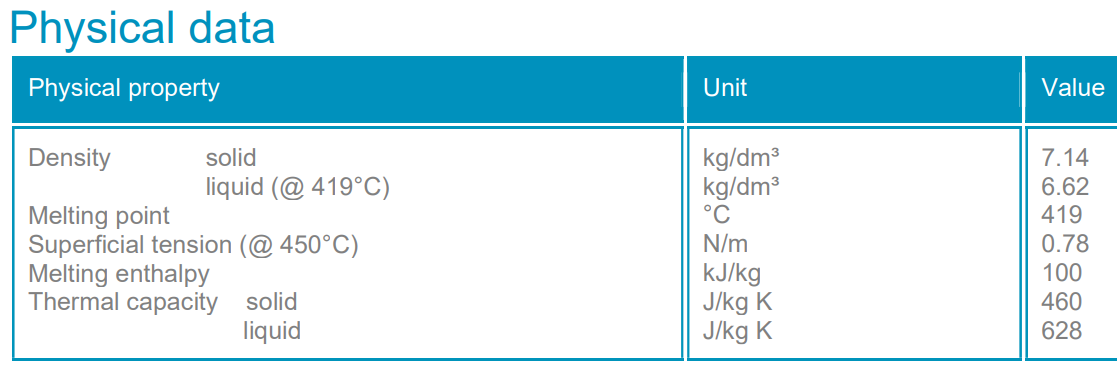

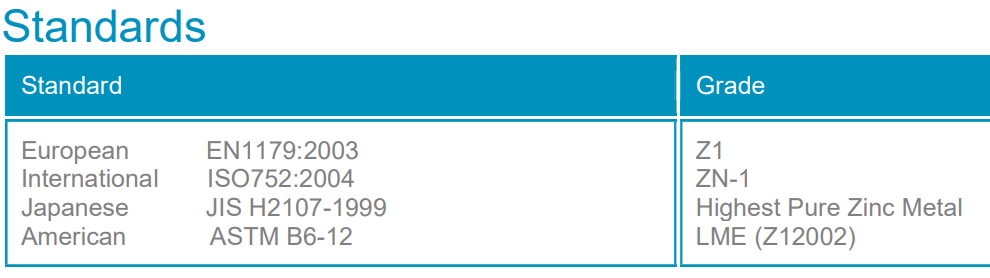

Zinc ash is processed to obtain metallic zinc of 99% minimum purity remelt zinc ingot. It is used in brass and hot dip galvanizing industries.

SPARPART Suppliers produces metallic Zinc Ingots with the highest possible density. Ingots are generally the least costly metallic form and useful in general applications. Our standard Ingot size is nominally 2-3 cm x 3-8 cm x 6-12 cm. Materials are produced using crystallization, solid state and other ultra-high purification processes such as sublimation. SPARPART Suppliers specializes in producing custom compositions for commercial and research applications and for new proprietary technologies. SPARPART Suppliers also casts any of the rare earth metals and most other advanced materials into rod, bar, or plate form, as well as other machined shapes and through other processes such as nanoparticles and in the form of solutions and organometallics. We can also provide pieces and shot in smaller ranges

Shipping Policy

According to your country. Click on "Request for inquiry" and specify your country

We will send you our offer CFR.

Based on 0 reviews

Be the first to review “Zinc ingot”

-

Guillotine Shears

CNC VARIABLE RAKE HYDRAULIC GUILLOTINE SHEAR

General features

HYPER Series CNC Variable Rake Hydraulic Guillotine Shears that provide the appropriate solutions for your needs proved to be user-friendly with its advanced technological features produced with high efficiency, precision and performance criteria. The HYPER Series CNC Variable Rake HydraulicGuillotine Shears has proved to be the best and most durable in the industry with its ease of use.When you enter the length, thickness and material information of the sheet which will be cut into the easily programmable control unit; gap distance, cutting angle stroke and cutting length are automatically adjusted instantaneously.While providing flexibility for different production requirements, the time loss eliminated by targeting high productivity.• The machine frame manufactured with advanced technology with exact tolerances and stress relieved with welded components. All tensile points are designed with large radii and strain accumulation and possible welding cracks are eliminated.• The lower table and upper table inertia created for optimum value for the minimum deformation affecting the cutting quality.• The top plate designed to positioned vertically so that the roller bearings, piston bearings, and felts can compensate for vertical loads.• The hydraulic cylinder is intended to be double-sided and honed to surface quality of 2 microns. Thus, minimum wear resistance is created for the felts. The cylinder bodies manufactured as SAE 1040 material forged.• The hydraulic cylinders specially designed and the upper table mounted with cylinder springs and doubly secure to cylinders as a spherical connection. At this point, the power generated during cutting distributed to the machine body.• Piston head features: Omega-type felts fitted with full bronze bearings, semi-angled sleeves.• The Hilalsan hydraulic system allows precise usage at all pressure values up to the maximum operating pressure. At the same time, with these pressure values, precise cylinder positioning, synchronization, and repeatability are achieved.• Backgauge system manufactured in accordance with environmental conditions. Backgauge bearings made for heavy conditions with double bearers. Scrapping type bearings used against dust and other particles that will accumulate in the linear guideways against dusty environmental conditions.• The outer surface of the machine is painted with two layers of paint at least 60 microns in thickness to protect against weather conditions. Paint drying is done gradually in a different time and temperature ranges in state-of-the-art ovens.SKU: n/a

There are no reviews yet.